Ever noticed how the name “plasma cutter” sounds so futuristic? Ironically, this tool has been in use since early 1960s, and it continues to be used for achieving quick and perfect metal cuts. In fact this cutting tool has almost completely replaced other traditional metal cutting methods both for commercial and domestic purposes. Just imagine how easy and convenient it would be to have a plasma cutter for all your DIY projects, without having to depend on others to have your metal parts cut in the way you desire! Yes, it’s true! The following review on the best plasma cutter will make your life more comfortable, especially as it comes with a buying guide and other crucial information that will help you learn more about this amazing cutting tool!

Ever noticed how the name “plasma cutter” sounds so futuristic? Ironically, this tool has been in use since early 1960s, and it continues to be used for achieving quick and perfect metal cuts. In fact this cutting tool has almost completely replaced other traditional metal cutting methods both for commercial and domestic purposes. Just imagine how easy and convenient it would be to have a plasma cutter for all your DIY projects, without having to depend on others to have your metal parts cut in the way you desire! Yes, it’s true! The following review on the best plasma cutter will make your life more comfortable, especially as it comes with a buying guide and other crucial information that will help you learn more about this amazing cutting tool!

What Is Plasma Cutter?

Essentially, plasma cutter is an advanced metal cutting tool that can cut through steel as well as other metals and materials. This cutting tool incorporates the use of inert gas that gets blown out from the cutter’s nozzle at extremely high speed for cutting the metal. Simultaneously, an arc (electrical) is also applied to this blown out inert gas, which converts the inert gas into plasm to form an extremely hot torch for cutting through any metal very conveniently and comfortably. Today’s plasma cutter ideas include several technologically advanced parts to ensure that you get the best results when cutting metals with these tools. The advanced portable designs and affordable prices are added factors that make these tools so popular. What is the best plasma cutter? Let’s read on plasma cutter reviews to get to know more about the products that have found their way in this list:

Lotos LTP5000D Plasma Cutter

Lotos LTP5000D 50Amp Non-Touch Pilot Arc Plasma Cutter, Dual Voltage 110V/220V, 1/2...

- This is a compact and sturdy plasma cutter that features a convenient handle that offers portability.

- It uses compressed air that is non-hazardous, for cutting alloy steel, aluminum, copper, stainless steel and mild steel.

- The machine features advanced Pilot Arc plasma torch that can easily cut through painted, rusty and rough surfaces, producing minimal slag.

- This Lotos plasma cutter comes with advanced PAPST cooling system (German) and MOSFET transistor to produce uniform output so that it can easily cut through thin metal sheets.

- The dual voltage feature of this product makes it possible to run this machine directly on 110V or 220V (both with 50/60 Hz).

- The package includes ground cable and clamp, air hose along with connections, air regulator and the plasma torch.

- It is a cost-effective, high-end solution

- The Pilot Arc advanced technology adds to the longevity of this machine’s consumables

- It can cut metal in a uniform and swift motion, regardless of the metal’s surface being rusted, painted or irregular

- It requires very low-pressure for operation

- The warranty on this product is only for a year

Lotos LTPDC2000D Plasma Cutter

Lotos Technology 04-ZVGR-0O8D Lotos LTPDC2000D Plasma Cutter Tig Stick Welder 3 in...

- This non-touch, Pilot Arc plasma cutter has the efficiency to smoothly cut through painted, rough as well as rusty surfaces without producing much slag

- The compact design of this machine comes with a handle that makes it the best portable plasma cutter

- It uses non-hazardous compressed air for cutting alloy steel, aluminum, copper, stainless steel and mild steel

- The TIG welding feature of this machine comes with 15-200A DC electric output to ensure high-quality welding on steel, as well as precise welding in case of thinner-gauge metals and materials

- This cutting tool comes with convenient ARC start, stabilized welding Arc, and a deep but efficient weld pool to provide amazing welding shape. The Hot Striking adjustable Arc Current enhances the function of ARC start, making it ideal for welding using various Basic or Acidic Electrodes.

- The product comes with 30-day Money-Back Guarantee as well as 1-year warranty.

- It is a durable machine, especially as it is made using “Infineon IGBT” matrix (power drive)

- You get to save a huge amount of money as this product is multifunctional

- It is easily portable and light in weight

- This machine’s welding leads are considerably small

Lotos LTPDC2000D User Manual

View this manualCarefully read the operation manual prior to using, installing and maintaining the electric welding machine for the purpose of preventing damages such as fire, electric shock and etc. from occurring. Please keep the manual for future reference.

Primeweld 50A Plasma Cutter

PRIMEWELD Premium & Rugged 50A Air Inverter Plasma Cutter Automatic Dual Voltage...

- The precision in metal cutting offered by this unit is unparalleled. It can work with 50 Ampere supply to cut metal as fine as 3/4″ in thickness without any hassle, making this machine perfect for both hobby use and commercial purpose.

- This plasma cutter can easily cut through alloy steel, aluminum, mild steel, copper, stainless steel and various other metals and materials, offering fine and precise cuts.

- It can be easily moved around for your project requirements, as it has been designed to be compact and lightweight.

- The MOSFET transistors in this unit ensure that you get any size or shape of metal you want using this metal cutter.

- It comes with 3-year warranty, adding to its reliability as one of the best plasma cutters available today.

- It is a cost-efficient plasma cutter

- This metal cutting tool can be easily cleaned, and its maintenance is also simple

- It is easily portable, which means that you can carry it around conveniently

- It is a highly versatile machine and can be used to cut a wide range of metals

- The product is very safe as it comes with built-in fire-preventive features

- It can be tough to initially figure out how this machine operates

Try the French shears or Metal shears to cut metals, especially sheets as thin as 20 gauges, as they can provide smooth shape.

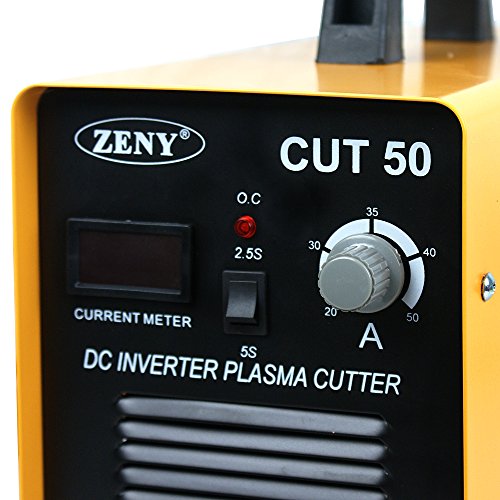

Zeny Cut 50 DC 50A Plasma Cutter

ZENY DC Inverter Plasma Cutter 50AMP CUT-50 Dual Voltage 110-220V Cutting Machine...

- Made from the most advanced technology, this unit is ideal for processing and cutting metals, both for DIY and industrial purposes.

- It is specifically designed to improve the quality of the metal cut, and its applications are wide including light industrial use, metal fabrication, site work, ducting work, automotive, maintenance and repair services.

- The product runs on current ranging between 20 and 50 Ampere, while its no-load voltage is 230V.

- The duty cycle of this machine is 60{%} and its efficiency is 85{%}.

- It has a maximum cutting capacity of 1-12 mm metal thickness.

- The design of this machine is lightweight, making it convenient for you to carry this unit around while working

- The product is reasonably-priced

- Setting up the machine is simple as well as easy, and even a newbie can set up this machine without any assistance

- The cuts delivered by this plasma cutter is highly impressive

- You can use this cutting tool on a wide range of metals

- It is difficult to read the user manual

- This unit does not perform well in terms of high-grade metal cutting

- You have to buy the plug and air hose separately, as they are not included in the package

The Cheap AF Plasma Cutter (Zeny Cut-50)

Yotube Video Review: The Cheap AF Plasma Cutter (Zeny Cut-50)

SungoldPower 50A Plasma Cutter

SUNGOLDPOWER 50A Air Plasma Cutter Inverter DC Digital Display IGBT Portable CUT50...

- Stable performance of the product is guaranteed due to its IGBT soft-switch technology.

- The high duty cycle of this cutting tool ensures that less power is consumed during its operation.

- The LCD display allows you to read the air pressure gauge easily without any hassle, and it operates very quietly.

- The machine comes with cutting current that can be adjusted to meet your metal cutting requirements.

- This product is safe to use as it features in-built over-voltage and overheat protection

- It is well-suited for cutting metals like stainless steel, copper, alloy steel, aluminum and even carbon steel among others.

- It is energy-efficient

- Uses IGBT soft-switch technology to offer stable performance

- LCD display for easy readability

- Precise and fine metal cutting capacity

- It is a bit highly-priced

Super Deal DC Plasma Cutter

Super Deal DC Inverter Plasma Cutter Machine With Screen Display Dual Voltage...

- The PRO technology used in this product ensures superior and stable performance.

- It consumes less power, which makes it more efficient and economical compared to other products in this category.

- The design of this product is also marvelous, as it made using quality heavy duty iron, giving its body a solid construction. This makes the machine more durable and reliable in terms of functionality and longevity.

- It comes with LCD display, easily readable air-pressure gauge (front panel), and is quiet during operation.

- The tool cuts smoothly at high speed, without requiring any further polishing on the metal

- The inbuilt over-voltage and overheat protection makes this unit extremely safe during use

- Priced pretty reasonably

- It is a multifunctional tool that works as a TIG welder, stick welder and a plasma cutter

- It runs very quietly

- It is a versatile machine that can be used for welding and cutting different varieties of metals

- It is easily portable

- Not all beginners can handle this unit

Goplus Cut-50 Plasma Cutter

Goplus CUT-50 Electric Digital Plasma Cutter Inverter 50AMP 110-220V Dual Voltage Welder...

- Using switch power inverter technical this unit can lower the weight and dimensions of the main transformer, increasing the efficiency of the unit by an impressive 30{%}.

- It features dual voltage ability, making it ideal to work with this cutting tool in 220V as well as 110V (with 60 Hz power).

- The design of this cutting tool is such that it enhances the portability of the machine, as it comes with a portable handle, allowing you to carry it around conveniently.

- The performance of this unit is not hampered by extremes in external environment, and it can easily function in very high or very low temperatures.

- It has a no-load voltage of 240V, which improves its efficiency

- It can easily support arc welding, making this diverse cutter perfect for both DC and AC use

- It can function perfectly well even in temperature that goes down to -10 degree Celsius, and more than 40 degree Celsius

- It does not get affected when the environment is mildly humid (with dampness as high as 80{%})

- Its cutting speed is very high, and it operates quietly

- The product can effectively save energy

- It requires a three-phase panel for supporting 220V

If you want to get the right shape of metal while cutting with a circular tool, you need to be firmly positioned on the floor so that you can get rid of any unwanted debris from the metal piece.

Lotos LT5000D

LOTOS LT5000D 50A Air Inverter Plasma Cutter Dual Voltage 110/220VAC 1/2" Clean...

- It features MOSFET inverter technology that enhances its metal cutting performance

- It is portable and lightweight in design

- The product offers fine repair on Chrome Moly, Steel and Stainless steel owning to its DC TIG feature

- The product features Pilot Arc technology based function that allows it to cut metals efficiently

- It has an amperage capacity of 200 A and draws power of 240V

- It requires DC current for operation and works on dual voltage of 220V and 110V

- It is a highly reliable product as the maker is well-reputed electronics manufacturer

- It draws very low current while working efficiently to cut through metals

- It does not require a lot of time for arc welding metals

- It comes with 3-year warranty and 30-day money-back guarantee

- The MOSFET technology-based design of this machine enhances its performance

- The price is not very high, but can be expensive to invest in this product

SuperUltra 206i User Manual

View this manualEverlast is dedicated to providing you with the best possible equipment and service to meet the demanding jobs that you have. We want to go beyond delivering a satisfactory product to you.

Lotos LTP7000 70A Plasma Cutter

LOTOS LTP7000 IGBT 70 Amps Pilot Arc Plasma Cutter

- The compact design of the machine along with a portable handle adds to convenience in carrying this unit around during work.

- The compressed air is non-hazardous and can efficiently cut mild steel, aluminum, stainless steel and copper, etc.

- The product comes with Pilot Arc based technology that makes it easy for you to cut metals that have rough, rusty or even painted surfaces without producing much slag

- The MOSFET transistor featured in this model ensures a uniform and precise output while cutting thin metal sheets

- It has the ability to cut metals with a thickness ranging between 7/8 inch and 1 ¼ inch

- It also comes with PAPST cooling system (advanced) to ensure safe operation

- The Pilot Arc Non-Touch technology ensures that you cut through metals without having to touch the metal

- The consumable life of this product is very long and it offers impressive cutting quality

- The tip is bulky to ensure a clean cut

- The handle of this machine makes it easy to carry the unit around while working

- The compressed air is non-hazardous, which enables the machine to easily cut through alloy steel, aluminum, copper and stainless steel among other metals

- The 60{%} duty cycle and PAPST based advanced cooling system (German) improves the performance of the unit

- It has issues in terms of clean cutting

Hobart 500566 40i Plasma Cutter

Hobart 500566 Airforce 40i Plasma Cutter 240V

- It has the ability to cut at a faster rate compared to oxy-fuel, as it comes with a duty cycle of 50{%}.

- This machine offers the benefit of cutting through perforated and expanded metals, along with metals that have coated or painted surfaces.

- It operates on an input power of 240V and has a maximum open-circuit voltage of 400V.

- The air consumption of this unit is highly efficient, and it also features trigger safety (ergonomic), which makes it ideal for use in heavy as well as light industries.

- The portable and lightweight design of this product gives you the advantage of carrying it around your workspace

- The cutting performance of this unit is powerful and precise

- It has the ability to cut through expanded metal as well as painted or coated surfaces

- Assembling the product is simple and easy

- The cutting torch can be operated comfortably

- You will not require any pressure setting or flame tuning to operate this machine

- It is an economical product that features a single-knob based design

- This model does not feature air compressor (internal), so you will need to make arrangements for the external supply

Hobart 500566 40i Plasma Cutter User Manual

View this manualPlease make sure to read and understand this manual before use.

| Product Name | Image | Rage | Overall Rating | Details |

|---|---|---|---|---|

| Lotos LTP5000D Plasma Cutter |

|

50 Amp | 8.5 | Check price |

| Lotos LTPDC2000D Plasma Cutter |

|

50 Amp | 9 | Check price |

| Primeweld 50A Plasma Cutter |

|

50 Amp | 10 | Check price |

| Zeny DC 50A Plasma Cutter |

|

50 Amp | 8 | Check price |

| SungoldPower 50A Plasma Cutter |

|

50 Amp | 8 | Check price |

| Super Deal DC Plasma Cutter |

|

50 Amp | 9.5 | Check price |

| Goplus Cut-50 Plasma Cutter |

|

50 Amp | 9 | Check price |

| LOTOS LT5000D |

|

50 Amp | 8.5 | Check price |

| Lotos LTP7000 70A Plasma Cutter |

|

70 Amp | 7.5 | Check price |

| Hobart 500566 40i Plasma Cutter |

|

40 Amp | 9.5 | Check price |

Types of Plasma Cutters

The following are the types of plasma cutters typically available these days:

- Manual

- Mechanized

A CNC plasma cutter is essentially a mechanized cutter and is generally larger in size than a manual cutter. Mechanized cutters also come with THC or torch height control that can be used for height sensing as well as voltage control. A mechanized plasma cutter table can be as large as 48 ft X 120 ft or as small as 4 ft X 8 ft, which affects the maneuvering of these machines during operation. However, these days you can also find mechanized portable plasma cutter in the market.

- Multifunctional

How To Choose A Plasma Cutter – Buyer’s Guide

The top cutters available today have already been listed out for you, but how do you know which one of these you should buy? Your plasma cutter purchase decision should be based on several important factors mentioned in the lines below: The very first consideration that you need to make is to decide the amount of metal thickness you will need to cut most of the time. Majority of the cutters get rated on the amperage and cutting ability they possess. This means that if you are looking for a cutter with the ability to swiftly cut through metals that have ¼ inch thickness, you need to opt for a cutter with lower amperage, and if you want to cut through thicker, you need to go for a cutter with higher amperage.

- Conduct Proper Test

- Easy Operation

You will also need to find out how easily you can operate the machine and how comfortable you feel using the unit. Make sure that the instruction manual of the cutter you choose is user-friendly and easy-to-read. This will help you when the machine is new, and you still need to learn how to use it. It will also help you understand better how to handle troubleshooting issues and assemblage of the machine when required for operation. The better the ergonomics of the machine, the more comfortable you will feel when using it. So, make sure that you invest in a unit that comes with great, comfy design.

- Safety Features Is A Must

How to Use The Machine

In order to learn how to use this metal cutting machine, you need to find out how you should set up the machine properly for operation. The following lines highlight the way you need to set up the machine for use:

Cutter Parts

Generally, a plasma cutter comes with the following parts: ASC or Arc Starting Console – This part is required for producing spark within the cutter for creating the arc that will cut the metal piece. The voltage requirement of the ASC is generally 5000V with 2 MHz frequency (AC). The Cutter – The cutter works to align the different consumable parts of the unit and to cool them accordingly. The plasma cutter tip, electrode and swirl ring are usually required for generating the arc and are aligned with the cutter. The retaining caps (outer and inner) of the cutter act as shields and hold the parts together in place.

Generally, a plasma cutter comes with the following parts: ASC or Arc Starting Console – This part is required for producing spark within the cutter for creating the arc that will cut the metal piece. The voltage requirement of the ASC is generally 5000V with 2 MHz frequency (AC). The Cutter – The cutter works to align the different consumable parts of the unit and to cool them accordingly. The plasma cutter tip, electrode and swirl ring are usually required for generating the arc and are aligned with the cutter. The retaining caps (outer and inner) of the cutter act as shields and hold the parts together in place.

Materials You Can Work With

Accessories like the plasma cutter drag shield and protective cage are also available in some of the best models in today’s market. The drag cap works to keep the nozzle safe while in use, while the protective cage ensures the safety of the sensitive inner parts during operation. You may also require protective gear while using this metal cutting machine, which is why investing in plasma cutter glasses can prove to be a good idea.

Accessories like the plasma cutter drag shield and protective cage are also available in some of the best models in today’s market. The drag cap works to keep the nozzle safe while in use, while the protective cage ensures the safety of the sensitive inner parts during operation. You may also require protective gear while using this metal cutting machine, which is why investing in plasma cutter glasses can prove to be a good idea.

Power Supply

Voltage Required

Advantages Of Using A Plasma Cutter

The reason why plasma cutters are so popular is that of the several benefits associated with using these machines. Here are some major advantages of using this metal cutting tool:

Safety Tips

While using this metal cutting unit, you need to take a few safety measures, especially if you are new to cutting metals.

- Make sure that the compressed air is clean and free of oil or water, as the presence of any of these can wear out the consumable parts, and eventually other parts as well.

- Check the air pressure and ensure that it is accurate.

- Make sure that the connection is proper, as it will ensure better performance of the machine.

- Ensure that the electrode and nozzle are in their proper place before starting your operation.

- Handle Nozzle Carefully- Don’t allow the nozzle of the machine to touch your workpiece, especially if you are working on a current level that is 45 Amperes and above. If you allow this to happen, then the lifespan of the nozzle will be reduced due to double arcing. Another reason why double arcing occurs is because the unit is dragged against a metal template. As a result, the nozzle is also dragged, causing it to wear out prematurely.

- Use Of Safety Gear- You need to follow the instruction manual carefully in order to understand how the machine works. Don’t forget to wear gloves and long sleeves before using the machine as molten metal produced during the process can injure your body. Also, make sure that you protect your eyes with welding shield or dark googles (with darkness shade ranging between #7 and #9) prior to beginning the process of metal cutting. And follow all the safety guideline and tips provided in the instruction manual.

- Maximum Current- When you are setting up the machine, make sure that the current is kept at maximum output initially. You can turn down the current later on as required, but initially maximum current will help you get best results.

- Direction To Maintain- In case you want to make a circular metal cut to get a round piece, you need to move in clockwise direction. Again, in case you don’t want to waste the remaining metal piece (From the circular cut), you need to move in a counter-clockwise direction. In order to get more precise and fine cut, you need to push your machine away from your body.

- Ensuring Work Distance- While working with this machine, you need to keep a distance of 1/8 to 3/16 inch from the unit’s nozzle. Also, don’t move the cutter in upward-downward fashion and it will hinder the effort you put in to cut the metal.

Size And Noise

Size And Noise

The two important aspects of a plasma cutter that affect their overall performance are: Most of today’s cutters are way more powerful than their predecessors, despite their small, compact size. They can be used to cut all kinds of materials and metals, right from 1inch metal plate to thin gauge sheets. While the traditional systems can cut through metals as thick as 2 inch or more, the ones mentioned in this review can efficiently deliver cuts on metals with a thickness under 2 inch. The ergonomic design of the plasma cutters reviewed above ensure smaller but more portable size, which can effectively help you carry these heavy-duty machines all around your workplace conveniently and comfortably. A big problem with such metal cutting machines is that they produce noise, not only physical but also electrical, the latter being caused by radiation of high frequency from within the system that interferes with the machine’s sensitive equipment. However, we have listed out only the best cutters in the market that are mostly silent during operation, i.e. they don’t create any physical noise, and come with reduced electrical noise caused by high frequency. Therefore, you can rest assured that no matter what product you choose from our list of best plasma cutters, it will come in portable size and will be noise-free.

The two important aspects of a plasma cutter that affect their overall performance are: Most of today’s cutters are way more powerful than their predecessors, despite their small, compact size. They can be used to cut all kinds of materials and metals, right from 1inch metal plate to thin gauge sheets. While the traditional systems can cut through metals as thick as 2 inch or more, the ones mentioned in this review can efficiently deliver cuts on metals with a thickness under 2 inch. The ergonomic design of the plasma cutters reviewed above ensure smaller but more portable size, which can effectively help you carry these heavy-duty machines all around your workplace conveniently and comfortably. A big problem with such metal cutting machines is that they produce noise, not only physical but also electrical, the latter being caused by radiation of high frequency from within the system that interferes with the machine’s sensitive equipment. However, we have listed out only the best cutters in the market that are mostly silent during operation, i.e. they don’t create any physical noise, and come with reduced electrical noise caused by high frequency. Therefore, you can rest assured that no matter what product you choose from our list of best plasma cutters, it will come in portable size and will be noise-free.

Design

As far as the design of this advanced metal cutting machine is concerned, it should be clear from the reviews that most of today’s plasma cutter designs include the following common aspects: The use of MOSFET and IGBT technologies ensure that the power supply remains constant and efficient during their operation so that the metal cuts are fine as well as precise. Also, the advanced Pilot Arc Technology ensures that metals with any kind of surface can be easily cut to get desired shape or size. They are easily portable as well as lightweight. Ergonomic design and lightweight materials used in these metal cutting tools offer you the benefit of easily carrying around the unit wherever required. They are extremely safe. The use of latest coolant system and in-built protection to prevent overheating contribute towards a safer and more secure operation.

As far as the design of this advanced metal cutting machine is concerned, it should be clear from the reviews that most of today’s plasma cutter designs include the following common aspects: The use of MOSFET and IGBT technologies ensure that the power supply remains constant and efficient during their operation so that the metal cuts are fine as well as precise. Also, the advanced Pilot Arc Technology ensures that metals with any kind of surface can be easily cut to get desired shape or size. They are easily portable as well as lightweight. Ergonomic design and lightweight materials used in these metal cutting tools offer you the benefit of easily carrying around the unit wherever required. They are extremely safe. The use of latest coolant system and in-built protection to prevent overheating contribute towards a safer and more secure operation.

Care And Maintenance

The only way to ensure great performance for a long time period you need to take care and maintain this advanced metal cutting machine.

- Don’t Ignore Replacing Consumable Parts– It is crucial that you replace the cutter’s consumable parts as regularly as possible, or if absolutely required. This will prevent the other parts from being damaged because of the consumable parts.

- Regular Cleaning- It is a must to clean the unit as frequently as possible. Make sure that you get rid of all signs of contamination and pollution as immediately as possible. The threads, both inside and outside, of the unit also must be cleaned (reserved crystal). You can use hydrogen peroxide to keep your unit dirt-free.

- Ensure Proper Assembly- Another important point to note is that the only way to ensure a longer lifespan of the cutting machine is by assembling it properly. Also, follow the manufacturer’s guidelines for cleaning and maintaining the unit.

- The Coolant And Gas Flow Should Be Appropriate– Make it your daily job to check the flow of gas and cooler pressure. Insufficient gas or coolant flow will lower the consumables’ lifespan, and will also affect the functioning of these parts. On the other hand, excessive gas pressure can result in hard starting.

- Make Sure You Use Appropriate Parts– In case you use a wrong consumable part, chances are that the cut quality and performance of the cutter will suffer. Eventually, the unit’s lifespan will also lessen over time. That’s why you need to choose and use only the right parts for your cutter.

Warranty

Size And Noise

Size And Noise